Tagging System

The setup is used to assign the correct energy and time to the bremsstrahlung photons. To determine the energy, the post-bremsstrahlung electron passes through the magnetic field of the tagger magnet and is deflected depending on its momentum. From the detection position in the hodoscope the electron momentum and energy can be determined and the energy of the photon can be calculated as the difference between the initial electron beam energy and the post-bremsstrahlung electron energy.

Radiators

| Material | Thickness / μm |

|

Copper |

50 |

|

Copper |

100 |

| Kapton | 125 |

| Copper+Kapton | 67+65 |

| Diamond+Kapton | 560+65 |

| Nickel-Steel wires | 400 |

| Chromox | 1000 |

Several radiators and monitoring tools are mounted on a goniometer inside a vacuum tank. While the amorphous radiators are used to produce incoherent bremsstrahlung, the diamond is used for coherent bremsstrahlung and thus produces a linearly polarised photon beam. The Chromox plate and Nickel-Steel wires are used for beam diagnostics.

With the goniometer the tools and radiators positions can be adjusted relative to the initial electron beam with high precision. This is especially important for the diamond, as the energetic range for the production of linearly polarised photons and subsequently the degree of polarisation of the produced photon beam is very sensitive to the orientation of the crystal lattice of the diamond with respect to the electron beam.

Being able to move the setup relative to the electron beam is also helpful for beam diagnostics. When placing the Chromox plate, a fluorescent screen made of Al2O3Cr, at 45° to the electron beam direction the beam position and shape can be observed as a flourescent spot with an external camera. For a more precise investigation of the beam profile two Nickel-Steel wires can be moved through the electron beam along the horizontal and vertical axes. While moving the wires through the beam the post bremsstrahlung electrons are counted. The total tagging rate with respect to the wire position gives a precise measurement of the electron beam position and profile.

Tagging Hodoscope

The tagger hodoscope consists of 120 overlapping scintillators. 54 are placed in the focal plane of the tagger magnet, while the other 66, due to spacing limitations, are arranged in a vertical construction. The covers a tagging range of about 10%E0 - 90%E0. One tagger channel is defined as a coincidence of two adjacent scintillators. The overlap of the scintillators is 55%. The scintillators are read out by either ET-Enterprise 9111 or Hamamatsu R7400U photomultipliers. A time resolution of 210 ps for the ET9111SB and of 180 ps for the Hamamatsu R7400U is achieved.

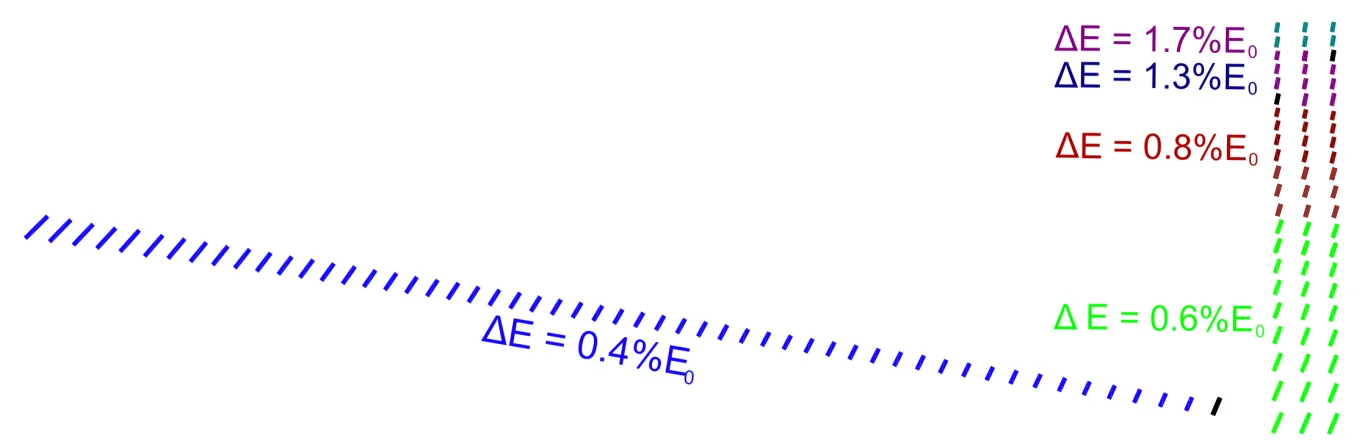

The energy resolution of the tagger is than defined by the overlapping areas of the scintillators. In the horizontal part, the width of the scintillators is chosen such, that the energy width of a coincidence is 0.40%E0. To assure coincidences with two neighbouring scintillators in the vertical tagger component, at least three appropriately tiltet scintillators are placed behind one another. For higher electron energies the electron tracks get closer to the primary beam above the vertical hodoscope part. To achieve a similar energy resolution as in the horizontal component, the width of the scintillators has to become smaller and therefore to assure an overlap of 55% three scintillators must be placed behind each other. The energy resolution achieved in the vertical part ranges from 0.60%E0 to 1.70%E0.

Argus

When using the diamond radiator the bremsstrahlung energy spectrum has an increase in rate in an energy range between 1.2 GeV and 1.8 GeV caused by coherent bremsstrahlung. The exact position of this polarisation peak is adjustable and highly dependent on the beam position and the orientation of the crystal lattice with respect to the beam. To monitor the position an increased energy resolution compared to what is achievable with the tagging hodoscope is necessary. This is achieved with ARGUS.

ARGUS is a scintillating fibre detector which is placed in front of the vertical part of the tagger. It consists of 480 double-clad BCF-10 round scintillating fibres, 2 mm diameter, from Saint Gobain, which are arranged in three layers. The readout is performed with 30 Hamamatsu H6568 multi-anode photomultipliers with 16 channels each.

The detector covers an energy range from 30% to 66% of the incoming ELSA electron energy, an energy resolution of 0.08% to 0.45% E0 is achieved. A spatial coincidence of the post-bremsstrahlung electron trajectory is required between ARGUS and the Photon Tagger Hodoscope. Time information is determined by the Photon Tagger Hodoscope, which has a better time resolution, compared to approximately 0.7 ns for ARGUS.